In the world of modern manufacturing, efficiency is key. Companies are constantly seeking ways to produce high-quality products faster, with fewer errors and less waste. One technology that has gained significant attention in recent years is Swiss CNC machining. This advanced method of manufacturing is known for its precision, speed, and ability to handle complex tasks that traditional machining struggles with. Understanding how Swiss CNC machining works and how it can be applied to your workflow can make a significant difference in productivity and overall efficiency.

Understanding Swiss CNC Machining

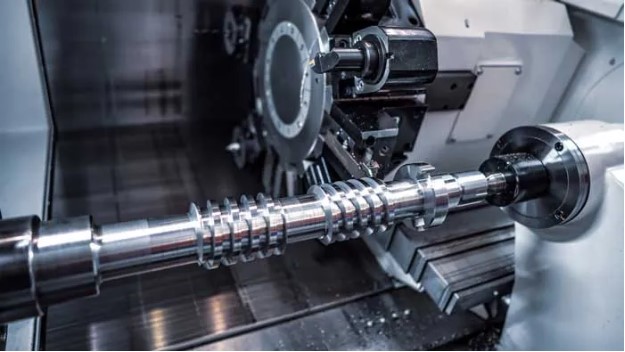

Swiss CNC machining, also called Swiss-type turning, is a specialized form of computer numerical control (CNC) machining. Unlike conventional CNC lathes, Swiss CNC machines hold the workpiece with a guide bushing, which provides support very close to the cutting tool. This setup allows for extremely precise and stable operations, even on very small or delicate components. Because of its design, Swiss CNC machining is particularly effective for producing long, thin, or intricate parts with tight tolerances.

The technology relies on automated control through computer programs, which ensures consistent accuracy from one part to the next. This means that manufacturers can produce high volumes of components without compromising on quality. Additionally, Swiss CNC machines can perform multiple operations in a single setup, reducing the need for manual intervention and saving time.

Faster Production Times

One of the main advantages of Swiss CNC machining is its ability to reduce production times. Because the machine can perform several cutting operations simultaneously and supports the workpiece closely, it eliminates many of the delays associated with repositioning or stabilizing parts. This leads to faster cycle times, allowing manufacturers to complete projects more quickly.

Moreover, the precision of Swiss CNC machining reduces errors that can slow down production. Parts that are machined accurately on the first attempt do not require rework, which saves both time and materials. In a manufacturing workflow where deadlines are critical, the speed and reliability of Swiss CNC machining can be a game-changer.

Improved Quality and Precision

Quality and precision are essential in any manufacturing process, and Swiss CNC machining excels in both. The design of the machine ensures that even the most complex or delicate components are machined with high accuracy. This is particularly important for industries such as medical devices, aerospace, and electronics, where even minor errors can lead to significant problems.

By integrating Swiss CNC machining into your workflow, you can consistently produce parts that meet exact specifications. The reduction in defects and variation enhances product reliability and customer satisfaction. Over time, this improvement in quality can also lead to reduced costs associated with returns, repairs, or warranty claims.

Reduced Waste and Lower Costs

Efficient manufacturing is not only about speed but also about minimizing waste. Swiss CNC machining contributes to waste reduction in several ways. Its precision cutting reduces material waste by producing parts closer to their final dimensions. The automation of the process also minimizes human error, which is often a source of scrap material.

Additionally, by combining multiple machining operations into a single setup, Swiss CNC machining reduces the need for multiple machines or manual handling. This streamlines the workflow, lowers labor costs, and optimizes resource use. The combination of less material waste, reduced rework, and more efficient labor results in significant cost savings for manufacturers.

Enhanced Flexibility and Workflow Integration

Swiss CNC machining is highly adaptable, which makes it easy to integrate into existing manufacturing workflows. It can handle a wide range of materials, including metals, plastics, and exotic alloys. Manufacturers can use the technology to produce both small batches and high-volume production runs without compromising efficiency.

The flexibility of Swiss CNC machining also supports innovation in design. Complex parts with intricate features can be produced with ease, allowing companies to meet customer demands for customized products. This adaptability ensures that your workflow remains efficient even as production requirements change.

Conclusion

Swiss CNC machining offers a powerful solution for manufacturers looking to improve efficiency in their workflows. By providing high precision, faster production times, reduced waste, and lower costs, this technology can transform the way components are produced. Its flexibility and ability to handle complex operations make it an ideal choice for a wide range of industries.

Integrating Swiss CNC machining into your manufacturing process is not just about adopting new technology; it is about creating a more streamlined, cost-effective, and reliable workflow. Companies that embrace this approach can expect improved productivity, higher-quality products, and a stronger competitive advantage in the market.